Aluminum Alloy GT Timing Pulley For Printing and Packaging Equipment

If you are looking for a reliable and high-quality timing pulley, then our Aluminum Alloy GT Timing Pulley for Printing and Packaging Equipment is the perfect choice for you. Made from premium quality aluminum alloy and stainless steel material, this pulley is designed to withstand heavy loads and provide long-lasting durability.

Product Description

Our Aluminum Alloy GT Timing Pulley is surface-treated with natural color anode to ensure excellent corrosion resistance and wear resistance. We also offer customized services such as light customization and logo customization to meet customers’ specific requirements. The product comes with a default engraving brand name and size; however, if you do not need engraving, you can contact our customer service for more information.

Packaging Details and Certifications

Our Aluminum Alloy GT Timing Pulley comes in a standard packaging with an anti-static package in a carton box. We also offer a wooden case for additional protection. Our products are ISO9001:2015 and IPMS certified, ensuring that you receive high-quality products that meet international standards.

Applicable Industries and Lead Time

Our Aluminum Alloy GT Timing Pulley is suitable for various industries, including Building Material Shops, Manufacturing Plants, Food & Beverage Factories, and Farms. The lead time for the product is 25 days, ensuring that you receive the product within the specified timeline.

Customization and Quality Control

We offer OEM and ODM services to create custom LOGO and products based on our customers’ requests. Our products undergo rigorous quality checks, including finished product inspection, and we also provide a warranty for our products.

Color and Surface Finish

Our Aluminum Alloy GT Timing Pulley comes in various colors such as silver, gold, black, red, blue, and customer-requested colors. The surface finish of the product is anodized, ensuring excellent wear and corrosion resistance.

Other Industrial Products

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, double pitch roller chains, planetary gearboxes, timing pulleys, pulleys, bushings, and more. We strive to provide high-quality products, affordable prices, and exceptional customer service. We welcome customers to customize their drawings and samples and contact us for any inquiries.

FAQs

1. What material is the Aluminum Alloy GT Timing Pulley made from?

– The pulley is made from premium quality aluminum alloy and stainless steel material.

2. Does the product come with customization options?

– Yes, we offer customized services such as light customization and logo customization to meet customers’ specific requirements.

3. What certifications do your products have?

– Our products are ISO9001:2015 and IPMS certified, ensuring high-quality products that meet international standards.

4. What is the lead time for the product?

– The lead time for the product is 25 days.

5. What other industrial products do you supply?

– Our company mainly supplies various products for industrial use, such as agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, double pitch roller chains, planetary gearboxes, timing pulleys, pulleys, bushings, and more.

Performance Characteristics of Timing Pulley

A timing pulley is a crucial component in various mechanical systems. It offers several performance characteristics that make it highly valuable in these applications.

1. Precise Synchronization: Timing pulleys are designed to maintain accurate synchronization between the driving and driven components. This ensures a smooth and efficient transfer of power.

2. High Efficiency: The toothed design of timing pulleys reduces slippage, resulting in improved power transmission efficiency. This is especially important in applications where precision and reliability are essential.

3. Low Noise and Vibration: Timing pulleys operate with minimal noise and vibration. This makes them suitable for applications that require quiet and smooth operation, such as robotics and CNC machines.

4. Wear Resistance: Timing pulleys are made from durable materials, such as aluminum, steel, or plastic, which offer excellent wear resistance. This enables them to withstand heavy loads and prolonged usage without compromising performance.

Types and Characteristics of Timing Pulley

Timing pulleys come in various types, each offering distinct characteristics to suit different applications.

1. MXL Timing Pulley: This type of timing pulley has a small pitch diameter, making it suitable for applications that require high positional accuracy.

2. HTD Timing Pulley: HTD (High Torque Drive) pulleys have a curvilinear tooth profile, providing increased tooth engagement and higher torque transmission capability.

3. GT Timing Pulley: GT (or GT2) pulleys have a trapezoidal tooth profile, offering high power transmission capacity and precise positioning.

The choice of timing pulley type depends on the specific requirements of the application.

Advantages of Timing Pulley Materials

Timing pulleys can be manufactured using different materials, each offering unique advantages.

1. Aluminum Timing Pulley: Lightweight and corrosion-resistant, aluminum pulleys are ideal for applications where weight reduction and durability are important, such as automotive and aerospace industries.

2. Steel Timing Pulley: Steel pulleys provide exceptional strength and durability, making them suitable for heavy-duty applications that require high load capacity and resistance to wear.

3. Plastic Timing Pulley: Plastic pulleys are lightweight, cost-effective, and offer excellent resistance to chemicals and corrosion. They are commonly used in applications where noise reduction is a priority.

The choice of material depends on factors such as load requirements, environmental conditions, and cost considerations.

Application of Timing Pulley

Timing pulleys find extensive use in various industries due to their versatility and reliability.

1. Robotics: Timing pulleys play a vital role in robotic systems, ensuring precise motion control and synchronization of robotic limbs and joints.

2. Automotive Industry: Timing pulleys are utilized in engines to drive camshafts, ensuring proper timing of valve functions and optimizing engine performance.

3. 3D Printers: Timing pulleys enable accurate movement of print heads and build platforms, resulting in precise and high-quality 3D prints.

4. CNC Machines: Timing pulleys are used in CNC machines to control the movement of axes, providing accurate positioning and enabling complex machining operations.

5. Conveyor Systems: Timing pulleys are crucial components in conveyor systems, facilitating the smooth and efficient transfer of goods in industries such as logistics and manufacturing.

The widespread application of timing pulleys highlights their importance in various industries and mechanical systems.

Future Development Trends and Opportunities

The future of timing pulley products is promising, with several trends and opportunities on the horizon.

1. Miniaturization: As technology advances, there is a growing demand for smaller and more compact timing pulleys to fit into miniaturized systems.

2. Lightweight Materials: The use of advanced lightweight materials, such as carbon fiber reinforced polymers, presents opportunities for developing timing pulleys with improved strength-to-weight ratios.

3. Automation and Robotics: With the increasing adoption of automation and robotics in various industries, the demand for precise timing pulleys will continue to grow.

4. Green Technology: The development of eco-friendly materials and manufacturing processes for timing pulleys aligns with the growing emphasis on sustainability and environmental responsibility.

Overall, the future of timing pulleys is characterized by innovation, efficiency, and sustainability, offering numerous opportunities for industry growth and advancement.

Choosing a Suitable Timing Pulley

Selecting the right timing pulley involves considering several key aspects:

1. Load Capacity: Determine the maximum load that the pulley will experience to ensure it can handle the required workload.

2. Material: Choose a material based on the specific application requirements, considering factors such as strength, weight, and resistance to wear and corrosion.

3. Diameter and Size: Select a pulley with an appropriate diameter and size to ensure compatibility with the system and achieve the desired speed and torque.

4. Type of Pulley: Select the appropriate type of timing pulley based on the application’s need for positional accuracy, torque transmission, or power capacity.

5. Bore Size: Ensure the timing pulley’s bore size matches the shaft diameter to guarantee a secure and reliable connection.

By carefully considering these aspects, you can choose a suitable timing pulley that meets the specific requirements of your application.

In conclusion, timing pulleys play a crucial role in various mechanical systems, offering precise synchronization, high efficiency, and low noise operation. Their different types and materials provide versatility for diverse applications. Timing pulleys find extensive use in industries such as robotics, automotive, 3D printing, CNC machining, and conveyor systems. The future of timing pulleys holds potential for miniaturization, lightweight materials, automation, and green technology. By considering load capacity, material, diameter and size, type of pulley, and bore size, one can select the most suitable timing pulley for their application.

Author: Dream

China Hot selling Timing Pulley Synchronous Belts V-Belt Sheaves Timing Belts and Synchronous Drive Parts Pulleys arb air compressor

China Hot Selling Timing Pulley Synchronous Belts V-Belt Sheaves Timing Belts and Synchronous Drive Parts Pulleys

Product Description

Timing Pulley Synchronous belts V-belt sheaves Timing Belts and Synchronous Drive Parts Pulleys

1) Warranty: Our timing pulleys come with a 1-year quality guarantee. If you encounter any quality issues upon receiving the products, you can return them for free maintenance.

2) Drawings: To get the best quotation, kindly send us the drawings of your timing pulleys. If you don’t have drawings, we can create CAD drawings and provide you with a quick quotation.

3) Sample: We accept sample orders, with a minimum order quantity of 1 piece. We will continue to make samples until you are satisfied.

4) Confidentiality agreement: We strictly adhere to client confidentiality agreements for timing pulleys.

| Product Description |

|

Product Name |

Timing Belt Pulley | |

| Teeth profile | Trapezoidal toothed | MXL, XXL, XL, L, H, XH, XXH |

| T-toothed | T2.5, T5, T10, T20 | |

| Arc toothed | HTD3M, HTD5M, HTD8M, HTD14M, HTD20M, Gt2, Gt3, Gt5 | |

| S-toothed | S2M, S3M, S4.5M, S5M, S8M, S14M | |

| Parabolic-toothed | P2M, P3M, P5M, P8M, P14M | |

| Y-toothed | G2M, G3M, G5M, Y8M | |

| Teeth Quantity | 10-150 teeth or customized | |

| Inner Bore | 2-200mm H7 precision or customized | |

| Belt width | 4mm, 6mm, 9mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 1/4”, 5/16”, 3/8”, 1/2”, 3/4”, 1”, 1.5”, 2”or customized | |

| Accessories | We can provide the service of assembling setscrews, bearings, shafts, or taper bush | |

| Surface treatment | Anodize, Black Oxide, Phosphate, and Galvanization | |

| Drawing Format | Timing belt pulley cad drawing, timing belt pulley UG drawing, Timing belt Pulley Soliwork drawing, Timing Pulley PDF drawing | |

What is a timing pulley?

Timing pulleys are specialized pulleys with teeth or pockets around their outer diameter. These teeth or pockets are used for timing, not for power transmission. They engage with holes or drive lugs on a belt’s inner circumference.

How do timing pulleys work?

The synchronous wheel transmission consists of an endless belt with equally spaced teeth on the inner peripheral surface and a pulley with corresponding teeth. During operation, the teeth of the belt mesh with the tooth grooves of the pulley, transmitting motion and power. This type of belt drive combines the advantages of transmission, chain drive, and gear transmission.

What is GT2 timing pulley?

GT2 pulleys have a 2mm pitch and are commonly used in 3D printing. They provide high precision and non-backlash due to their round tooth profile, making them popular in the Reprap community.

What is a timing pulley flange?

Timing pulley flanges are used to maintain belt contact with a timing pulley in power transmission applications. They are manufactured to fit timing pulleys of the same pitch and size, and their dimensions are specified by the number of grooves.

What are synchronous belts used for?

Synchronous belts with trapezoidal tooth profiles are commonly used in various applications such as machine tools, textile machinery, home appliances, business equipment, and as camshaft drives in engines.

Please note: To get our most complete CAD drawings and the best quotation, please provide us with the required information such as teeth profile, teeth quantity, belt width, bore diameter, quantity, and type (refer to the provided drawings).

Related Products

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, double pitch roller chains, timing pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. We emphasize high-quality products, preferential prices, and considerate services. Customers are welcome to customize drawings and samples.

Frequently Asked Questions (FAQs)

1. Are the timing pulleys covered by a warranty?

Yes, our timing pulleys come with a 1-year warranty. If you encounter any quality issues, you can return them for free maintenance.

2. Can I get a quotation without providing drawings?

Yes, if you don’t have drawings, please let us know, and we can create CAD drawings for you and provide a quick quotation.

3. Is it possible to order a sample of the timing pulleys?

Yes, we accept sample orders with a minimum quantity of 1 piece. We will continue to make samples until you are satisfied.

4. Do you adhere to client confidentiality agreements?

Yes, we strictly adhere to client confidentiality agreements for timing pulleys.

5. What other products does your company supply?

In addition to timing pulleys, our company supplies various industrial products such as agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, double pitch roller chains, planetary gearboxes, bushings, etc. We are committed to providing high-quality products, competitive prices, and excellent customer service.

Performance Characteristics of Timing Pulley

A timing pulley is a crucial component in various mechanical systems. It offers several performance characteristics that make it highly valuable in these applications.

1. Precise Synchronization: Timing pulleys are designed to maintain accurate synchronization between the driving and driven components. This ensures a smooth and efficient transfer of power.

2. High Efficiency: The toothed design of timing pulleys reduces slippage, resulting in improved power transmission efficiency. This is especially important in applications where precision and reliability are essential.

3. Low Noise and Vibration: Timing pulleys operate with minimal noise and vibration. This makes them suitable for applications that require quiet and smooth operation, such as robotics and CNC machines.

4. Wear Resistance: Timing pulleys are made from durable materials, such as aluminum, steel, or plastic, which offer excellent wear resistance. This enables them to withstand heavy loads and prolonged usage without compromising performance.

Types and Characteristics of Timing Pulley

Timing pulleys come in various types, each offering distinct characteristics to suit different applications.

1. MXL Timing Pulley: This type of timing pulley has a small pitch diameter, making it suitable for applications that require high positional accuracy.

2. HTD Timing Pulley: HTD (High Torque Drive) pulleys have a curvilinear tooth profile, providing increased tooth engagement and higher torque transmission capability.

3. GT Timing Pulley: GT (or GT2) pulleys have a trapezoidal tooth profile, offering high power transmission capacity and precise positioning.

The choice of timing pulley type depends on the specific requirements of the application.

Advantages of Timing Pulley Materials

Timing pulleys can be manufactured using different materials, each offering unique advantages.

1. Aluminum Timing Pulley: Lightweight and corrosion-resistant, aluminum pulleys are ideal for applications where weight reduction and durability are important, such as automotive and aerospace industries.

2. Steel Timing Pulley: Steel pulleys provide exceptional strength and durability, making them suitable for heavy-duty applications that require high load capacity and resistance to wear.

3. Plastic Timing Pulley: Plastic pulleys are lightweight, cost-effective, and offer excellent resistance to chemicals and corrosion. They are commonly used in applications where noise reduction is a priority.

The choice of material depends on factors such as load requirements, environmental conditions, and cost considerations.

Application of Timing Pulley

Timing pulleys find extensive use in various industries due to their versatility and reliability.

1. Robotics: Timing pulleys play a vital role in robotic systems, ensuring precise motion control and synchronization of robotic limbs and joints.

2. Automotive Industry: Timing pulleys are utilized in engines to drive camshafts, ensuring proper timing of valve functions and optimizing engine performance.

3. 3D Printers: Timing pulleys enable accurate movement of print heads and build platforms, resulting in precise and high-quality 3D prints.

4. CNC Machines: Timing pulleys are used in CNC machines to control the movement of axes, providing accurate positioning and enabling complex machining operations.

5. Conveyor Systems: Timing pulleys are crucial components in conveyor systems, facilitating the smooth and efficient transfer of goods in industries such as logistics and manufacturing.

The widespread application of timing pulleys highlights their importance in various industries and mechanical systems.

Future Development Trends and Opportunities

The future of timing pulley products is promising, with several trends and opportunities on the horizon.

1. Miniaturization: As technology advances, there is a growing demand for smaller and more compact timing pulleys to fit into miniaturized systems.

2. Lightweight Materials: The use of advanced lightweight materials, such as carbon fiber reinforced polymers, presents opportunities for developing timing pulleys with improved strength-to-weight ratios.

3. Automation and Robotics: With the increasing adoption of automation and robotics in various industries, the demand for precise timing pulleys will continue to grow.

4. Green Technology: The development of eco-friendly materials and manufacturing processes for timing pulleys aligns with the growing emphasis on sustainability and environmental responsibility.

Overall, the future of timing pulleys is characterized by innovation, efficiency, and sustainability, offering numerous opportunities for industry growth and advancement.

Choosing a Suitable Timing Pulley

Selecting the right timing pulley involves considering several key aspects:

1. Load Capacity: Determine the maximum load that the pulley will experience to ensure it can handle the required workload.

2. Material: Choose a material based on the specific application requirements, considering factors such as strength, weight, and resistance to wear and corrosion.

3. Diameter and Size: Select a pulley with an appropriate diameter and size to ensure compatibility with the system and achieve the desired speed and torque.

4. Type of Pulley: Select the appropriate type of timing pulley based on the application’s need for positional accuracy, torque transmission, or power capacity.

5. Bore Size: Ensure the timing pulley’s bore size matches the shaft diameter to guarantee a secure and reliable connection.

By carefully considering these aspects, you can choose a suitable timing pulley that meets the specific requirements of your application.

In conclusion, timing pulleys play a crucial role in various mechanical systems, offering precise synchronization, high efficiency, and low noise operation. Their different types and materials provide versatility for diverse applications. Timing pulleys find extensive use in industries such as robotics, automotive, 3D printing, CNC machining, and conveyor systems. The future of timing pulleys holds potential for miniaturization, lightweight materials, automation, and green technology. By considering load capacity, material, diameter and size, type of pulley, and bore size, one can select the most suitable timing pulley for their application.

Author: Dream

China wholesaler Factory Price Wholesale High Precision Wheel Power Transmission Parts 5 Gt Timing Belt Pulley air compressor for sale

China Wholesaler Factory: High Precision Wheel Power Transmission Parts 5 GT Timing Belt Pulley for Sale

The China Wholesaler Factory offers a wide range of high precision wheel power transmission parts, including the 5 GT timing belt pulley. Our timing belt pulleys are designed to provide efficient and reliable power transmission in various industrial applications. With our factory price and wholesale options, you can get these top-quality products at competitive rates.

Product Description

Our timing belt pulleys are made using durable materials such as 6061 aluminum, S45C steel, and SUS304 stainless steel. This ensures their long-lasting performance and resistance to wear and tear. The teeth profile options include HTD3M, 5M, 8M, 14M, MXL, XL, L, H, S2M, S3M, S5M, S8M, 2GT, 3GT, 5GT, 8YU, T2.5, T5, T10, AT5, AT10, and more. You can choose from different basic shapes, including Type A, B, D, E, F, and K. The teeth quantity ranges from 10 to 150 teeth, and customization is available.

Our timing belt pulleys have a belt width range of 4-50mm and come with various inner bore options, including H7 precision or customized dimensions. Bore types include taper hole, pilot bore, round hole, and keyway hole. We also offer different surface treatments such as anodize, black oxide, phosphate, and galvanization, ensuring corrosion resistance and enhanced durability.

Our products are certified under ISO9001:2008, guaranteeing their high quality and reliability. We utilize advanced testing equipment such as projecting apparatus, salt spray test, durometer, and coating thickness tester. Our producing equipment includes CNC machines, automatic lathe machines, stamping machines, CNC milling machines, rolling machines, lasering, and tag grinding machines, ensuring precise and efficient manufacturing.

Our timing belt pulleys find application in various industries including the robot industry, medical industry, machinery manufacturing, automation industry, 3C industry, packaging industry, UAV industry, and new energy industry.

Certifications

Our products are manufactured in compliance with international standards. We hold certifications to ensure the quality and reliability of our timing belt pulleys.

FAQs

Q1. What is the advantage of purchasing our timing belt pulleys?

Our timing belt pulleys are made with high precision and durable materials, ensuring long-lasting performance. We offer a wide range of options and customization services to meet your specific requirements. With our competitive prices and excellent customer service, you can trust us as your reliable supplier.

Q2. Do you guarantee the quality of your timing belt pulleys?

Yes, we guarantee the quality of our timing belt pulleys. We conduct pre-production samples and final inspections to ensure that each product meets the highest standards before shipment.

Q3. What other products do you offer?

In addition to timing belt pulleys, we supply various power transmission parts, CNC parts, FA factory automation parts, flanges, agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, double pitch roller chains, planetary gearboxes, timing pulleys and pulleys, and bushings. We have a team of technical engineers who can provide customized solutions based on your drawings and samples.

Q4. Why choose us as your supplier?

We stand out from other suppliers because of our high precision CNC parts, competitive prices, and one-stop solution for FA factory automation parts. Our products are designed for superior performance and durability. We prioritize customer satisfaction and offer considerate services along with high-quality products.

Q5. What services do you provide?

We provide various delivery terms, including FOB, CFR, CIF, EXW, and express delivery. Accepted payment currencies include USD, EUR, and CNY. Payment options include T/T, L/C, D/P, D/A, MoneyGram, Credit Card, PayPal, and Western Union. We have multilingual support in English and Chinese to assist you with your inquiries and orders.

Choose our China Wholesaler Factory for top-quality power transmission parts and excellent services. Contact us today to discuss your specific requirements and benefit from our competitive prices and customized solutions.

Disclaimer: Our company primarily focuses on supplying industrial products such as the mentioned power transmission parts. For more information about our full range of products, please contact us.

Performance Characteristics of Timing Pulley

A timing pulley is a crucial component in various mechanical systems. It offers several performance characteristics that make it highly valuable in these applications.

1. Precise Synchronization: Timing pulleys are designed to maintain accurate synchronization between the driving and driven components. This ensures a smooth and efficient transfer of power.

2. High Efficiency: The toothed design of timing pulleys reduces slippage, resulting in improved power transmission efficiency. This is especially important in applications where precision and reliability are essential.

3. Low Noise and Vibration: Timing pulleys operate with minimal noise and vibration. This makes them suitable for applications that require quiet and smooth operation, such as robotics and CNC machines.

4. Wear Resistance: Timing pulleys are made from durable materials, such as aluminum, steel, or plastic, which offer excellent wear resistance. This enables them to withstand heavy loads and prolonged usage without compromising performance.

Types and Characteristics of Timing Pulley

Timing pulleys come in various types, each offering distinct characteristics to suit different applications.

1. MXL Timing Pulley: This type of timing pulley has a small pitch diameter, making it suitable for applications that require high positional accuracy.

2. HTD Timing Pulley: HTD (High Torque Drive) pulleys have a curvilinear tooth profile, providing increased tooth engagement and higher torque transmission capability.

3. GT Timing Pulley: GT (or GT2) pulleys have a trapezoidal tooth profile, offering high power transmission capacity and precise positioning.

The choice of timing pulley type depends on the specific requirements of the application.

Advantages of Timing Pulley Materials

Timing pulleys can be manufactured using different materials, each offering unique advantages.

1. Aluminum Timing Pulley: Lightweight and corrosion-resistant, aluminum pulleys are ideal for applications where weight reduction and durability are important, such as automotive and aerospace industries.

2. Steel Timing Pulley: Steel pulleys provide exceptional strength and durability, making them suitable for heavy-duty applications that require high load capacity and resistance to wear.

3. Plastic Timing Pulley: Plastic pulleys are lightweight, cost-effective, and offer excellent resistance to chemicals and corrosion. They are commonly used in applications where noise reduction is a priority.

The choice of material depends on factors such as load requirements, environmental conditions, and cost considerations.

Application of Timing Pulley

Timing pulleys find extensive use in various industries due to their versatility and reliability.

1. Robotics: Timing pulleys play a vital role in robotic systems, ensuring precise motion control and synchronization of robotic limbs and joints.

2. Automotive Industry: Timing pulleys are utilized in engines to drive camshafts, ensuring proper timing of valve functions and optimizing engine performance.

3. 3D Printers: Timing pulleys enable accurate movement of print heads and build platforms, resulting in precise and high-quality 3D prints.

4. CNC Machines: Timing pulleys are used in CNC machines to control the movement of axes, providing accurate positioning and enabling complex machining operations.

5. Conveyor Systems: Timing pulleys are crucial components in conveyor systems, facilitating the smooth and efficient transfer of goods in industries such as logistics and manufacturing.

The widespread application of timing pulleys highlights their importance in various industries and mechanical systems.

Future Development Trends and Opportunities

The future of timing pulley products is promising, with several trends and opportunities on the horizon.

1. Miniaturization: As technology advances, there is a growing demand for smaller and more compact timing pulleys to fit into miniaturized systems.

2. Lightweight Materials: The use of advanced lightweight materials, such as carbon fiber reinforced polymers, presents opportunities for developing timing pulleys with improved strength-to-weight ratios.

3. Automation and Robotics: With the increasing adoption of automation and robotics in various industries, the demand for precise timing pulleys will continue to grow.

4. Green Technology: The development of eco-friendly materials and manufacturing processes for timing pulleys aligns with the growing emphasis on sustainability and environmental responsibility.

Overall, the future of timing pulleys is characterized by innovation, efficiency, and sustainability, offering numerous opportunities for industry growth and advancement.

Choosing a Suitable Timing Pulley

Selecting the right timing pulley involves considering several key aspects:

1. Load Capacity: Determine the maximum load that the pulley will experience to ensure it can handle the required workload.

2. Material: Choose a material based on the specific application requirements, considering factors such as strength, weight, and resistance to wear and corrosion.

3. Diameter and Size: Select a pulley with an appropriate diameter and size to ensure compatibility with the system and achieve the desired speed and torque.

4. Type of Pulley: Select the appropriate type of timing pulley based on the application’s need for positional accuracy, torque transmission, or power capacity.

5. Bore Size: Ensure the timing pulley’s bore size matches the shaft diameter to guarantee a secure and reliable connection.

By carefully considering these aspects, you can choose a suitable timing pulley that meets the specific requirements of your application.

In conclusion, timing pulleys play a crucial role in various mechanical systems, offering precise synchronization, high efficiency, and low noise operation. Their different types and materials provide versatility for diverse applications. Timing pulleys find extensive use in industries such as robotics, automotive, 3D printing, CNC machining, and conveyor systems. The future of timing pulleys holds potential for miniaturization, lightweight materials, automation, and green technology. By considering load capacity, material, diameter and size, type of pulley, and bore size, one can select the most suitable timing pulley for their application.

Author: Dream

China Good quality Agricultural Synchronous Aluminum Timing Spinning Taper Lock Bush Idler Flat Poly Grooved Sheave Wheel Adjustable Crankshaft Alternator Tension V Belt Pulley with Best Sales

China Good Quality Agricultural Synchronous Aluminum Timing Spinning Taper Lock Bush Idler Flat Poly Grooved Sheave Wheel Adjustable Crankshaft Alternator Tension V Belt Pulley

Product Description

Pulleys belonging to wheel hub components are generally large in size, and their manufacturing processes are mainly casting and forging. Generally, the design with large size is cast iron (good casting performance), and cast steel is rarely used (poor casting performance); Generally, the smaller size can be designed as forgings and the material is steel.

Belt pulley is mainly used for long-distance power transmission, such as the output of small diesel engines, agricultural vehicles, tractors, automobiles, mining machinery, mechanical processing equipment, textile machinery, packaging machinery, lathes, forging machines, power transmission of some small horsepower motorcycles, power transmission of agricultural machinery, air compressors, reducers, generators, cotton ginners, etc.

V-Belt Pulley:

The specifications of V-belts are divided by the dimensions of back width (top width) and height (thickness). According to different dimensions of back width (top width) and height (thickness), V-belts of different standards have different models. The pitch width, top width and height of V-belts of each model are different, so the pulley must also make various groove types according to the shape of V-belts; These different groove types determine various types of pulley.

| American Standard | |

AK/AKH BK/BKH TA/TB/TC Series Sheaves |

B/C/D Series Sheaves |

Poly-V Sheaves |

Variable Speed Sheaves |

| 3V/5V/8V sheaves | Bushings Split Taper Bushings/QD Bushings/TB Bushings |

European standard (SPA CHINAMFG SPC SPZ) |

|

Belt Pulleys for Taper Bushings |

V belt pulley with CHINAMFG hub |

Adjustable Speed V Belt Pulleys |

Flat Belt Pulleys For Taper Bushes |

Timing pulley:

The synchronous pulley drive is composed of a closed annular belt with equidistant teeth on the inner surface and corresponding pulley. When moving, the belt teeth mesh with the grooves of the belt pulley to transmit motion and power. It is a kind of meshing transmission, which has various characteristics of gear transmission, chain transmission, and belt transmission. Widely used in automobile, textile, printing and packaging equipment, sewing equipment, office equipment, laser carving equipment, tobacco, financial machinery, stage lighting, communication and food machinery, medical machinery, steel machinery, petrochemical industry, instruments and meters, various precision machine tools, and other fields.

Spinning pulley:

Spinning is to fix the flat or hollow blank on the mold of the spinning machine. When the blank rotates with the main shaft of the machine, the blank is pressurized with a roller or driving rod to produce local plastic deformation. Spinning is a special forming method.

Agricultural pulley:

Agricultural pulley refers to the parts that can be used to repair and replace your agricultural machinery pulley, such as the lawn mower and rotary tiller. Our agricultural pulley can perfectly replace various brands, including John Deere.

Custom pulley:

Bore type: pilot bore, finished bore, taper bore, bore for QD bushing.

Surface finish: Black oxide, phosphate, painted, Zinc plate, or passivated.

Material: 5C, cast iron, ductile iron, GG25, GGG40, nylon, aluminum, etc.

Inspection: Dynamic balance & Static balance tests are available with standardized design and well-equipped CNC Machining Systems.

Made according to drawings or samples, OEM inquiries are welcomed.

Related products

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, Double pitch roller chains, timing pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. We are committed to providing high-quality products, preferential prices, and considerate services. Customers are welcome to customize drawings and samples.

FAQs

1. What are the main applications of agricultural pulleys?

Agricultural pulleys are mainly used in agricultural machinery such as lawn mowers and rotary tillers.

2. What materials are custom pulleys made of?

Custom pulleys can be made from materials such as 5C, cast iron, ductile iron, GG25, GGG40, nylon, and aluminum.

3. What is the purpose of a timing pulley?

A timing pulley is used in synchronous pulley drives to transmit motion and power in various industries such as automobile, textile, printing, packaging, and more.

4. What are the different types of V-belt pulleys?

V-belt pulleys come in various types such as AK/AKH BK/BKH TA/TB/TC Series Sheaves, B/C/D Series Sheaves, Poly-V Sheaves, Variable Speed Sheaves, and more.

5. What is the significance of bore types in custom pulleys?

Bore types in custom pulleys, such as pilot bore, finished bore, taper bore, and bore for QD bushing, determine the fitting and mounting options for different applications.

Performance Characteristics of Timing Pulley

A timing pulley is a crucial component in various mechanical systems. It offers several performance characteristics that make it highly valuable in these applications.

1. Precise Synchronization: Timing pulleys are designed to maintain accurate synchronization between the driving and driven components. This ensures a smooth and efficient transfer of power.

2. High Efficiency: The toothed design of timing pulleys reduces slippage, resulting in improved power transmission efficiency. This is especially important in applications where precision and reliability are essential.

3. Low Noise and Vibration: Timing pulleys operate with minimal noise and vibration. This makes them suitable for applications that require quiet and smooth operation, such as robotics and CNC machines.

4. Wear Resistance: Timing pulleys are made from durable materials, such as aluminum, steel, or plastic, which offer excellent wear resistance. This enables them to withstand heavy loads and prolonged usage without compromising performance.

Types and Characteristics of Timing Pulley

Timing pulleys come in various types, each offering distinct characteristics to suit different applications.

1. MXL Timing Pulley: This type of timing pulley has a small pitch diameter, making it suitable for applications that require high positional accuracy.

2. HTD Timing Pulley: HTD (High Torque Drive) pulleys have a curvilinear tooth profile, providing increased tooth engagement and higher torque transmission capability.

3. GT Timing Pulley: GT (or GT2) pulleys have a trapezoidal tooth profile, offering high power transmission capacity and precise positioning.

The choice of timing pulley type depends on the specific requirements of the application.

Advantages of Timing Pulley Materials

Timing pulleys can be manufactured using different materials, each offering unique advantages.

1. Aluminum Timing Pulley: Lightweight and corrosion-resistant, aluminum pulleys are ideal for applications where weight reduction and durability are important, such as automotive and aerospace industries.

2. Steel Timing Pulley: Steel pulleys provide exceptional strength and durability, making them suitable for heavy-duty applications that require high load capacity and resistance to wear.

3. Plastic Timing Pulley: Plastic pulleys are lightweight, cost-effective, and offer excellent resistance to chemicals and corrosion. They are commonly used in applications where noise reduction is a priority.

The choice of material depends on factors such as load requirements, environmental conditions, and cost considerations.

Application of Timing Pulley

Timing pulleys find extensive use in various industries due to their versatility and reliability.

1. Robotics: Timing pulleys play a vital role in robotic systems, ensuring precise motion control and synchronization of robotic limbs and joints.

2. Automotive Industry: Timing pulleys are utilized in engines to drive camshafts, ensuring proper timing of valve functions and optimizing engine performance.

3. 3D Printers: Timing pulleys enable accurate movement of print heads and build platforms, resulting in precise and high-quality 3D prints.

4. CNC Machines: Timing pulleys are used in CNC machines to control the movement of axes, providing accurate positioning and enabling complex machining operations.

5. Conveyor Systems: Timing pulleys are crucial components in conveyor systems, facilitating the smooth and efficient transfer of goods in industries such as logistics and manufacturing.

The widespread application of timing pulleys highlights their importance in various industries and mechanical systems.

Future Development Trends and Opportunities

The future of timing pulley products is promising, with several trends and opportunities on the horizon.

1. Miniaturization: As technology advances, there is a growing demand for smaller and more compact timing pulleys to fit into miniaturized systems.

2. Lightweight Materials: The use of advanced lightweight materials, such as carbon fiber reinforced polymers, presents opportunities for developing timing pulleys with improved strength-to-weight ratios.

3. Automation and Robotics: With the increasing adoption of automation and robotics in various industries, the demand for precise timing pulleys will continue to grow.

4. Green Technology: The development of eco-friendly materials and manufacturing processes for timing pulleys aligns with the growing emphasis on sustainability and environmental responsibility.

Overall, the future of timing pulleys is characterized by innovation, efficiency, and sustainability, offering numerous opportunities for industry growth and advancement.

Choosing a Suitable Timing Pulley

Selecting the right timing pulley involves considering several key aspects:

1. Load Capacity: Determine the maximum load that the pulley will experience to ensure it can handle the required workload.

2. Material: Choose a material based on the specific application requirements, considering factors such as strength, weight, and resistance to wear and corrosion.

3. Diameter and Size: Select a pulley with an appropriate diameter and size to ensure compatibility with the system and achieve the desired speed and torque.

4. Type of Pulley: Select the appropriate type of timing pulley based on the application’s need for positional accuracy, torque transmission, or power capacity.

5. Bore Size: Ensure the timing pulley’s bore size matches the shaft diameter to guarantee a secure and reliable connection.

By carefully considering these aspects, you can choose a suitable timing pulley that meets the specific requirements of your application.

In conclusion, timing pulleys play a crucial role in various mechanical systems, offering precise synchronization, high efficiency, and low noise operation. Their different types and materials provide versatility for diverse applications. Timing pulleys find extensive use in industries such as robotics, automotive, 3D printing, CNC machining, and conveyor systems. The future of timing pulleys holds potential for miniaturization, lightweight materials, automation, and green technology. By considering load capacity, material, diameter and size, type of pulley, and bore size, one can select the most suitable timing pulley for their application.

Author: Dream

China supplier Industry Leading Ribbed Rubber Belt Seamless Auto Motorcycle Oil Resistant Timing Pulley with high quality

High-Quality China Supplier Industry Leading Ribbed Rubber Belt Seamless Auto Motorcycle Oil Resistant Timing Pulley

This China supplier industry leading ribbed rubber belt seamless auto motorcycle oil resistant timing pulley is a high-quality product that is designed to provide accurate transmission, balance, low noise, and no slip. It is also multi-axis transmission, oil-resistant, moisture-proof, and requires no lubrication. This timing pulley is made of carbon steel, aluminum alloy, brass, and cast iron. It can be customized according to the customer’s needs, including the teeth profile, teeth quantity, belt width, bore diameter, quantity, and type.

Features

This timing pulley has several features that make it stand out from other similar products:

- Accurate transmission: This timing pulley is designed to provide accurate transmission, ensuring that your machinery runs smoothly and efficiently.

- Balance: The timing pulley is well-balanced, meaning that it won’t cause any unwanted vibrations or wobbling.

- Low noise: It operates quietly and smoothly, so it won’t disturb your work environment.

- No slip: The timing pulley has a secure grip, so it won’t slip or come loose.

- Multi-axis transmission: This timing pulley allows for multi-axis transmission, which means it can be used in a wide variety of machinery.

- Oil-resistant: It is designed to be oil-resistant, which makes it ideal for use in environments where oil is present.

- Moisture-proof: The timing pulley is moisture-proof, so you don’t have to worry about it rusting or corroding over time.

- No lubrication required: This timing pulley does not require any lubrication, which means you can save time and money on maintenance.

- Safety and eco-friendly: It is made with safety and environmental concerns in mind, so you can feel good about using it.

- Wide range of applications: This timing pulley can be used in a variety of industrial applications, including machining, mining accessories, machinery accessories, truck parts, auto parts, and industrial parts.

- Customizable: This timing pulley can be customized according to your specific needs, including teeth profile, teeth quantity, belt width, bore diameter, quantity, and type.

Specifications

This timing pulley has the following specifications:

- Teeth profile: Arc toothed, arc Gt toothed, trapezoidal toothed, T-toothed, AT-toothed, S-toothed, parabolic-toothed, Y-toothed.

- Teeth quantity: 10-150 teeth or customized.

- Inner bore: 2-200mm H7 precision or customized.

- Materials: Carbon steel, aluminum alloy frequently used, brass and cast iron available.

- Surface treatment: Anodize, black oxide, phosphate, and galvanization.

- Specification: OEM service, strictly according to drawing and samples.

FAQs

1. How is the quality of this timing pulley ensured?

All our processes strictly adhere to ISO9001:2008 procedures, and we have strict quality control from producing to delivery. Our products are SGS, RoHS, M1, and UL certified. We also provide small samples for testing to ensure quality.

2. Can I get a sample of this timing pulley?

Yes, sample orders are welcomed.

3. Can I customize this timing pulley according to my specific needs?

Yes, this timing pulley can be customized according to your specific requirements, including teeth profile, teeth quantity, belt width, bore diameter, quantity, and type.

4. Does your company offer any discounts?

Yes, we will try our best to provide you with the best price and service possible.

5. What other industrial products does your company supply?

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, double pitch roller chains, timing pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. Customers are welcome to customize drawings and samples.

Performance Characteristics of Timing Pulley

A timing pulley is a crucial component in various mechanical systems. It offers several performance characteristics that make it highly valuable in these applications.

1. Precise Synchronization: Timing pulleys are designed to maintain accurate synchronization between the driving and driven components. This ensures a smooth and efficient transfer of power.

2. High Efficiency: The toothed design of timing pulleys reduces slippage, resulting in improved power transmission efficiency. This is especially important in applications where precision and reliability are essential.

3. Low Noise and Vibration: Timing pulleys operate with minimal noise and vibration. This makes them suitable for applications that require quiet and smooth operation, such as robotics and CNC machines.

4. Wear Resistance: Timing pulleys are made from durable materials, such as aluminum, steel, or plastic, which offer excellent wear resistance. This enables them to withstand heavy loads and prolonged usage without compromising performance.

Types and Characteristics of Timing Pulley

Timing pulleys come in various types, each offering distinct characteristics to suit different applications.

1. MXL Timing Pulley: This type of timing pulley has a small pitch diameter, making it suitable for applications that require high positional accuracy.

2. HTD Timing Pulley: HTD (High Torque Drive) pulleys have a curvilinear tooth profile, providing increased tooth engagement and higher torque transmission capability.

3. GT Timing Pulley: GT (or GT2) pulleys have a trapezoidal tooth profile, offering high power transmission capacity and precise positioning.

The choice of timing pulley type depends on the specific requirements of the application.

Advantages of Timing Pulley Materials

Timing pulleys can be manufactured using different materials, each offering unique advantages.

1. Aluminum Timing Pulley: Lightweight and corrosion-resistant, aluminum pulleys are ideal for applications where weight reduction and durability are important, such as automotive and aerospace industries.

2. Steel Timing Pulley: Steel pulleys provide exceptional strength and durability, making them suitable for heavy-duty applications that require high load capacity and resistance to wear.

3. Plastic Timing Pulley: Plastic pulleys are lightweight, cost-effective, and offer excellent resistance to chemicals and corrosion. They are commonly used in applications where noise reduction is a priority.

The choice of material depends on factors such as load requirements, environmental conditions, and cost considerations.

Application of Timing Pulley

Timing pulleys find extensive use in various industries due to their versatility and reliability.

1. Robotics: Timing pulleys play a vital role in robotic systems, ensuring precise motion control and synchronization of robotic limbs and joints.

2. Automotive Industry: Timing pulleys are utilized in engines to drive camshafts, ensuring proper timing of valve functions and optimizing engine performance.

3. 3D Printers: Timing pulleys enable accurate movement of print heads and build platforms, resulting in precise and high-quality 3D prints.

4. CNC Machines: Timing pulleys are used in CNC machines to control the movement of axes, providing accurate positioning and enabling complex machining operations.

5. Conveyor Systems: Timing pulleys are crucial components in conveyor systems, facilitating the smooth and efficient transfer of goods in industries such as logistics and manufacturing.

The widespread application of timing pulleys highlights their importance in various industries and mechanical systems.

Future Development Trends and Opportunities

The future of timing pulley products is promising, with several trends and opportunities on the horizon.

1. Miniaturization: As technology advances, there is a growing demand for smaller and more compact timing pulleys to fit into miniaturized systems.

2. Lightweight Materials: The use of advanced lightweight materials, such as carbon fiber reinforced polymers, presents opportunities for developing timing pulleys with improved strength-to-weight ratios.

3. Automation and Robotics: With the increasing adoption of automation and robotics in various industries, the demand for precise timing pulleys will continue to grow.

4. Green Technology: The development of eco-friendly materials and manufacturing processes for timing pulleys aligns with the growing emphasis on sustainability and environmental responsibility.

Overall, the future of timing pulleys is characterized by innovation, efficiency, and sustainability, offering numerous opportunities for industry growth and advancement.

Choosing a Suitable Timing Pulley

Selecting the right timing pulley involves considering several key aspects:

1. Load Capacity: Determine the maximum load that the pulley will experience to ensure it can handle the required workload.

2. Material: Choose a material based on the specific application requirements, considering factors such as strength, weight, and resistance to wear and corrosion.

3. Diameter and Size: Select a pulley with an appropriate diameter and size to ensure compatibility with the system and achieve the desired speed and torque.

4. Type of Pulley: Select the appropriate type of timing pulley based on the application’s need for positional accuracy, torque transmission, or power capacity.

5. Bore Size: Ensure the timing pulley’s bore size matches the shaft diameter to guarantee a secure and reliable connection.

By carefully considering these aspects, you can choose a suitable timing pulley that meets the specific requirements of your application.

In conclusion, timing pulleys play a crucial role in various mechanical systems, offering precise synchronization, high efficiency, and low noise operation. Their different types and materials provide versatility for diverse applications. Timing pulleys find extensive use in industries such as robotics, automotive, 3D printing, CNC machining, and conveyor systems. The future of timing pulleys holds potential for miniaturization, lightweight materials, automation, and green technology. By considering load capacity, material, diameter and size, type of pulley, and bore size, one can select the most suitable timing pulley for their application.

Author: Dream

China manufacturer Timing Belt Tensioner Pulley 17540-63r30 Tensioner Bearing lowes air compressor

China Manufacturer Timing Belt Tensioner Pulley 17540-63R30 Tensioner Bearing for Lowes Air Compressor

Looking for a high-quality timing belt tensioner pulley for your air compressor? Look no further than our China-manufactured tensioner pulley, compatible with the 17540-63R30 OEM. Our tensioner pulleys are made from top-quality materials and undergo 100% testing to ensure their durability and reliability.

Product Specifications:

Our tensioner pulleys come in a standard size and a natural color. The minimum order quantity is 20 pieces, and they come in neutral packaging.

| Product Name: | Tensioner Pulley |

|---|---|

| Quality: | High Quality 100% Test |

| OEM: | 17540-63R30 |

| Size: | Standard Size |

| MOQ: | 20pcs |

| Color: | Natural Color |

| Package: | Neutral Packing |

Other Industrial Products We Offer:

In addition to our tensioner pulleys, we also offer a wide range of products for industrial use, including:

- Agricultural Gearboxes

- Shafts

- Sprockets

- Fluid Couplings

- Worm Gear Reducers

- Gears and Racks

- Double Pitch Roller Chains

- Timing Pulleys and Pulleys

- Planetary Gearboxes

- Bushings

At our company, we pride ourselves on offering high-quality products at preferential prices, backed by considerate services. We welcome customers to customize drawings and samples according to their specific needs.

Frequently Asked Questions:

1. What is the minimum order quantity for the tensioner pulleys?

The minimum order quantity is 20 pieces.

2. What is the OEM for the tensioner pulleys?

The OEM for the tensioner pulleys is 17540-63R30.

3. What other industrial products does your company offer?

In addition to tensioner pulleys, we offer agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, double pitch roller chains, timing pulleys and pulleys, planetary gearboxes, bushings, and more.

4. Can customers customize drawings and samples?

Yes, we welcome customers to customize drawings and samples according to their specific needs.

5. What sets your company apart from other suppliers?

Our company prides itself on offering high-quality products at preferential prices, backed by considerate services. We also welcome customers to customize drawings and samples according to their specific needs.

Performance Characteristics of Timing Pulley

A timing pulley is a crucial component in various mechanical systems. It offers several performance characteristics that make it highly valuable in these applications.

1. Precise Synchronization: Timing pulleys are designed to maintain accurate synchronization between the driving and driven components. This ensures a smooth and efficient transfer of power.

2. High Efficiency: The toothed design of timing pulleys reduces slippage, resulting in improved power transmission efficiency. This is especially important in applications where precision and reliability are essential.

3. Low Noise and Vibration: Timing pulleys operate with minimal noise and vibration. This makes them suitable for applications that require quiet and smooth operation, such as robotics and CNC machines.

4. Wear Resistance: Timing pulleys are made from durable materials, such as aluminum, steel, or plastic, which offer excellent wear resistance. This enables them to withstand heavy loads and prolonged usage without compromising performance.

Types and Characteristics of Timing Pulley

Timing pulleys come in various types, each offering distinct characteristics to suit different applications.

1. MXL Timing Pulley: This type of timing pulley has a small pitch diameter, making it suitable for applications that require high positional accuracy.

2. HTD Timing Pulley: HTD (High Torque Drive) pulleys have a curvilinear tooth profile, providing increased tooth engagement and higher torque transmission capability.

3. GT Timing Pulley: GT (or GT2) pulleys have a trapezoidal tooth profile, offering high power transmission capacity and precise positioning.

The choice of timing pulley type depends on the specific requirements of the application.

Advantages of Timing Pulley Materials

Timing pulleys can be manufactured using different materials, each offering unique advantages.

1. Aluminum Timing Pulley: Lightweight and corrosion-resistant, aluminum pulleys are ideal for applications where weight reduction and durability are important, such as automotive and aerospace industries.

2. Steel Timing Pulley: Steel pulleys provide exceptional strength and durability, making them suitable for heavy-duty applications that require high load capacity and resistance to wear.

3. Plastic Timing Pulley: Plastic pulleys are lightweight, cost-effective, and offer excellent resistance to chemicals and corrosion. They are commonly used in applications where noise reduction is a priority.

The choice of material depends on factors such as load requirements, environmental conditions, and cost considerations.

Application of Timing Pulley

Timing pulleys find extensive use in various industries due to their versatility and reliability.

1. Robotics: Timing pulleys play a vital role in robotic systems, ensuring precise motion control and synchronization of robotic limbs and joints.

2. Automotive Industry: Timing pulleys are utilized in engines to drive camshafts, ensuring proper timing of valve functions and optimizing engine performance.

3. 3D Printers: Timing pulleys enable accurate movement of print heads and build platforms, resulting in precise and high-quality 3D prints.

4. CNC Machines: Timing pulleys are used in CNC machines to control the movement of axes, providing accurate positioning and enabling complex machining operations.

5. Conveyor Systems: Timing pulleys are crucial components in conveyor systems, facilitating the smooth and efficient transfer of goods in industries such as logistics and manufacturing.

The widespread application of timing pulleys highlights their importance in various industries and mechanical systems.

Future Development Trends and Opportunities

The future of timing pulley products is promising, with several trends and opportunities on the horizon.

1. Miniaturization: As technology advances, there is a growing demand for smaller and more compact timing pulleys to fit into miniaturized systems.

2. Lightweight Materials: The use of advanced lightweight materials, such as carbon fiber reinforced polymers, presents opportunities for developing timing pulleys with improved strength-to-weight ratios.

3. Automation and Robotics: With the increasing adoption of automation and robotics in various industries, the demand for precise timing pulleys will continue to grow.

4. Green Technology: The development of eco-friendly materials and manufacturing processes for timing pulleys aligns with the growing emphasis on sustainability and environmental responsibility.

Overall, the future of timing pulleys is characterized by innovation, efficiency, and sustainability, offering numerous opportunities for industry growth and advancement.

Choosing a Suitable Timing Pulley

Selecting the right timing pulley involves considering several key aspects:

1. Load Capacity: Determine the maximum load that the pulley will experience to ensure it can handle the required workload.

2. Material: Choose a material based on the specific application requirements, considering factors such as strength, weight, and resistance to wear and corrosion.

3. Diameter and Size: Select a pulley with an appropriate diameter and size to ensure compatibility with the system and achieve the desired speed and torque.

4. Type of Pulley: Select the appropriate type of timing pulley based on the application’s need for positional accuracy, torque transmission, or power capacity.

5. Bore Size: Ensure the timing pulley’s bore size matches the shaft diameter to guarantee a secure and reliable connection.

By carefully considering these aspects, you can choose a suitable timing pulley that meets the specific requirements of your application.

In conclusion, timing pulleys play a crucial role in various mechanical systems, offering precise synchronization, high efficiency, and low noise operation. Their different types and materials provide versatility for diverse applications. Timing pulleys find extensive use in industries such as robotics, automotive, 3D printing, CNC machining, and conveyor systems. The future of timing pulleys holds potential for miniaturization, lightweight materials, automation, and green technology. By considering load capacity, material, diameter and size, type of pulley, and bore size, one can select the most suitable timing pulley for their application.

Author: Dream

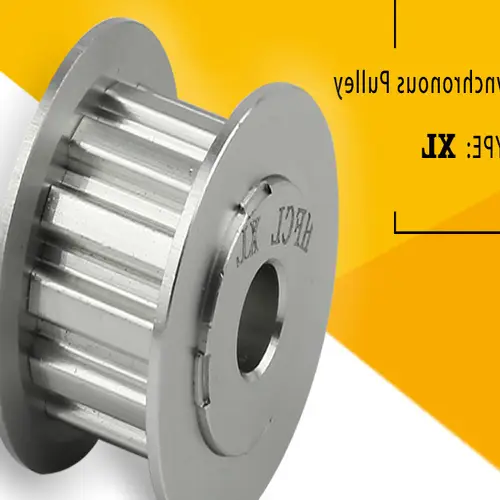

China Hot selling OEM ODM Mxl XL L H Pitch Timing Pulley for Automatic Machine air compressor price

XL Pitch Timing Pulley for Automatic Machines

Synchronous belt pulleys are an essential component of belt transmission systems that aid in the smooth transmission of power and motion. These pulleys come equipped with toothed slots that mesh with the teeth of a synchronous belt, which helps transmit motion and power efficiently.

Our XL pitch timing pulleys are an ideal choice for automatic machines, thanks to their superior performance and reliability. They are available in a range of teeth types, including MXL, XL, L, H, XH, XXH, and more, making them suitable for a broad spectrum of applications.

Features of Our XL Pitch Timing Pulleys

Our XL pitch timing pulleys are manufactured with high precision and accuracy to ensure optimal performance. The following are some of the key features of our timing pulleys:

- Customizable teeth type and adaption

- Natural color anodizing, black anodizing, hard anodizing, Ni-plating, blackening surface treatments available

- Made using high-quality materials such as 6061 aluminum, S45C 45# steel, SUS304 stainless steel

- Available in pilot bore, taper bore, and customized bore options

- Tolerance control of outer diameter ±0.005mm and length dimension ±0.05mm

- Meets DIN, ISO/GB, AGMA, JIS standards for teeth accuracy

- Can support a weight of up to 15 tons

- Manufactured using advanced machining processes such as gear hobbing, gear milling, gear shaping, gear broaching, gear shaving, gear grinding, and gear lapping

- Used in a wide range of industries such as robotics, medical, automation, packaging, and more

Other Products We Offer

In addition to XL pitch timing pulleys, our company offers a wide range of industrial products such as agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, double pitch roller chains, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on offering high-quality products at preferential prices, backed by excellent customer service. We welcome custom orders based on drawings or samples.

Frequently Asked Questions (FAQs)

-

What is a synchronous belt pulley and how does it work?

A synchronous belt pulley is an essential component of belt transmission systems that meshes with the teeth of a synchronous belt to transmit motion and power efficiently. During operation, the belt teeth mesh with the tooth slots of the belt pulley, allowing for the smooth transmission of motion and power.

-

What materials are used to manufacture your XL pitch timing pulleys?

Our XL pitch timing pulleys are manufactured using high-quality materials such as 6061 aluminum, S45C 45# steel, and SUS304 stainless steel, ensuring optimal performance and durability.

-

What industries are your XL pitch timing pulleys suitable for?

Our XL pitch timing pulleys are suitable for a wide range of industries such as robotics, medical, automation, packaging, and more, thanks to their superior performance and reliability.

-

What customization options are available for your XL pitch timing pulleys?

We offer a range of customization options for our XL pitch timing pulleys, including teeth type, adaption, surface treatment, bore options, and more, allowing for optimal customization based on specific requirements.

-

What standards do your XL pitch timing pulleys meet?

Our XL pitch timing pulleys meet DIN, ISO/GB, AGMA, JIS standards for teeth accuracy, ensuring the highest levels of precision and accuracy for optimal performance.

Performance Characteristics of Timing Pulley

A timing pulley is a crucial component in various mechanical systems. It offers several performance characteristics that make it highly valuable in these applications.

1. Precise Synchronization: Timing pulleys are designed to maintain accurate synchronization between the driving and driven components. This ensures a smooth and efficient transfer of power.

2. High Efficiency: The toothed design of timing pulleys reduces slippage, resulting in improved power transmission efficiency. This is especially important in applications where precision and reliability are essential.

3. Low Noise and Vibration: Timing pulleys operate with minimal noise and vibration. This makes them suitable for applications that require quiet and smooth operation, such as robotics and CNC machines.

4. Wear Resistance: Timing pulleys are made from durable materials, such as aluminum, steel, or plastic, which offer excellent wear resistance. This enables them to withstand heavy loads and prolonged usage without compromising performance.

Types and Characteristics of Timing Pulley

Timing pulleys come in various types, each offering distinct characteristics to suit different applications.

1. MXL Timing Pulley: This type of timing pulley has a small pitch diameter, making it suitable for applications that require high positional accuracy.

2. HTD Timing Pulley: HTD (High Torque Drive) pulleys have a curvilinear tooth profile, providing increased tooth engagement and higher torque transmission capability.

3. GT Timing Pulley: GT (or GT2) pulleys have a trapezoidal tooth profile, offering high power transmission capacity and precise positioning.

The choice of timing pulley type depends on the specific requirements of the application.

Advantages of Timing Pulley Materials

Timing pulleys can be manufactured using different materials, each offering unique advantages.

1. Aluminum Timing Pulley: Lightweight and corrosion-resistant, aluminum pulleys are ideal for applications where weight reduction and durability are important, such as automotive and aerospace industries.

2. Steel Timing Pulley: Steel pulleys provide exceptional strength and durability, making them suitable for heavy-duty applications that require high load capacity and resistance to wear.

3. Plastic Timing Pulley: Plastic pulleys are lightweight, cost-effective, and offer excellent resistance to chemicals and corrosion. They are commonly used in applications where noise reduction is a priority.

The choice of material depends on factors such as load requirements, environmental conditions, and cost considerations.

Application of Timing Pulley

Timing pulleys find extensive use in various industries due to their versatility and reliability.

1. Robotics: Timing pulleys play a vital role in robotic systems, ensuring precise motion control and synchronization of robotic limbs and joints.

2. Automotive Industry: Timing pulleys are utilized in engines to drive camshafts, ensuring proper timing of valve functions and optimizing engine performance.

3. 3D Printers: Timing pulleys enable accurate movement of print heads and build platforms, resulting in precise and high-quality 3D prints.

4. CNC Machines: Timing pulleys are used in CNC machines to control the movement of axes, providing accurate positioning and enabling complex machining operations.

5. Conveyor Systems: Timing pulleys are crucial components in conveyor systems, facilitating the smooth and efficient transfer of goods in industries such as logistics and manufacturing.

The widespread application of timing pulleys highlights their importance in various industries and mechanical systems.

Future Development Trends and Opportunities

The future of timing pulley products is promising, with several trends and opportunities on the horizon.

1. Miniaturization: As technology advances, there is a growing demand for smaller and more compact timing pulleys to fit into miniaturized systems.

2. Lightweight Materials: The use of advanced lightweight materials, such as carbon fiber reinforced polymers, presents opportunities for developing timing pulleys with improved strength-to-weight ratios.

3. Automation and Robotics: With the increasing adoption of automation and robotics in various industries, the demand for precise timing pulleys will continue to grow.

4. Green Technology: The development of eco-friendly materials and manufacturing processes for timing pulleys aligns with the growing emphasis on sustainability and environmental responsibility.

Overall, the future of timing pulleys is characterized by innovation, efficiency, and sustainability, offering numerous opportunities for industry growth and advancement.

Choosing a Suitable Timing Pulley

Selecting the right timing pulley involves considering several key aspects:

1. Load Capacity: Determine the maximum load that the pulley will experience to ensure it can handle the required workload.

2. Material: Choose a material based on the specific application requirements, considering factors such as strength, weight, and resistance to wear and corrosion.

3. Diameter and Size: Select a pulley with an appropriate diameter and size to ensure compatibility with the system and achieve the desired speed and torque.

4. Type of Pulley: Select the appropriate type of timing pulley based on the application’s need for positional accuracy, torque transmission, or power capacity.

5. Bore Size: Ensure the timing pulley’s bore size matches the shaft diameter to guarantee a secure and reliable connection.

By carefully considering these aspects, you can choose a suitable timing pulley that meets the specific requirements of your application.

In conclusion, timing pulleys play a crucial role in various mechanical systems, offering precise synchronization, high efficiency, and low noise operation. Their different types and materials provide versatility for diverse applications. Timing pulleys find extensive use in industries such as robotics, automotive, 3D printing, CNC machining, and conveyor systems. The future of timing pulleys holds potential for miniaturization, lightweight materials, automation, and green technology. By considering load capacity, material, diameter and size, type of pulley, and bore size, one can select the most suitable timing pulley for their application.

Author: Dream

China Custom Auto Parts Engine Water Pump Tensioner Timing Belt Pulley with Best Sales

Custom Auto Parts Engine Water Pump Tensioner Timing Belt Pulley with Best Sales

The custom auto parts engine water pump tensioner timing belt pulley is an essential component of synchronous belt drive. It is suitable for the MC11/13 ENGINE and also suited for D20/26(D2066LF40). The product is made of powdered metals, which have significant cost savings and high-quality finished products. Powdered metals also allow for the creation of complex or unique shapes with no or minimal waste during production. The production process of powder metallurgy includes powder mixing, forming, sintering, oil impregnation, sizing, ultrasonic cleaning, steam oxidation, oil impregnation, final inspection, and packing.

How to Choose Synchronous Pulleys?

When selecting a model, actual parameters should be combined. It is necessary to determine the required number of teeth, pitch diameter, and structure of the synchronous wheel product based on the tooth shape model of the synchronous belt and synchronous belt wheel, as well as the pitch and other related parameters of the synchronous belt and synchronous wheel. The calculation of the number of teeth and diameter of the synchronous wheel first requires the calculation of the number of teeth of the small synchronous wheel, and then the number of teeth of the large synchronous wheel is determined based on the transmission ratio of the synchronous wheel transmission system.

In order to ensure the service life of the synchronous wheel, the diameter of the small synchronous wheel should be larger than the minimum allowable bending diameter of the synchronous wheel, and then the minimum number of teeth of the synchronous wheel should be calculated based on the data. When the structure and cost allow, factors such as the service life of the synchronous belt should be considered. The number of teeth of the small synchronous wheel should be slightly larger than the allowable minimum size, which is ideal. When determining the number of teeth on the small synchronous wheel, the number of teeth on the large synchronous wheel is determined based on the transmission ratio of the synchronous wheel transmission system, and finally, the center distance between the 2 synchronous wheels is determined based on the synchronous wheel transmission structure.

FAQs:

1. What is the custom auto parts engine water pump tensioner timing belt pulley?

The custom auto parts engine water pump tensioner timing belt pulley is an essential component of synchronous belt drive.

2. What is the production process of powder metallurgy?

The production process of powder metallurgy includes powder mixing, forming, sintering, oil impregnation, sizing, ultrasonic cleaning, steam oxidation, oil impregnation, final inspection, and packing.

3. How to choose synchronous pulleys?

When selecting a model, actual parameters should be combined. It is necessary to determine the required number of teeth, pitch diameter, and structure of the synchronous wheel product based on the tooth shape model of the synchronous belt and synchronous belt wheel, as well as the pitch and other related parameters of the synchronous belt and synchronous wheel.

4. What are the benefits of using powdered metals?

Powdered metals have significant cost savings, the ability to create complex or unique shapes, no or minimal waste during production, and high-quality finished products.

5. What other industrial products does the company offer?

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, Double pitch roller chains, timing pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. Customers are welcome to customize drawings and samples.

Performance Characteristics of Timing Pulley